Contact Form HP

We will get back to you as soon as possible.

Please try again later.

Masterbatch

Masterbatch Processing Hardware and Assistance

The masterbatch process is one of the most integral parts of the manufacturing process. It plays a critical role in ensuring that the end product has the qualities it needs to perform its intended use effectively. Whether you need a high-shear or a low-shear blend, Polymers Technology has the hardware to achieve the end product you are looking for.

What Is A Masterbatch?

A masterbatch is a concentrated blend of additives, and/or fillers that are added to a base plastic product. The plastic additives in the masterbatch are what design/mold plastics to fit their intended use. Fillers impart other properties onto the material (influencing melting point, stiffness, etc.).

The properties of the plastic additives will have an impact on the final product's appearance and performance. The blends are usually premixed and are added to a large volume of polymer in small amounts. Depending on the end use of the product, the blend could include the following:

- Processing aids

- Fire retardants

- Antistats

- Light stabilizers

- Fillers

- Carrier resins

- Colorants

- And more.

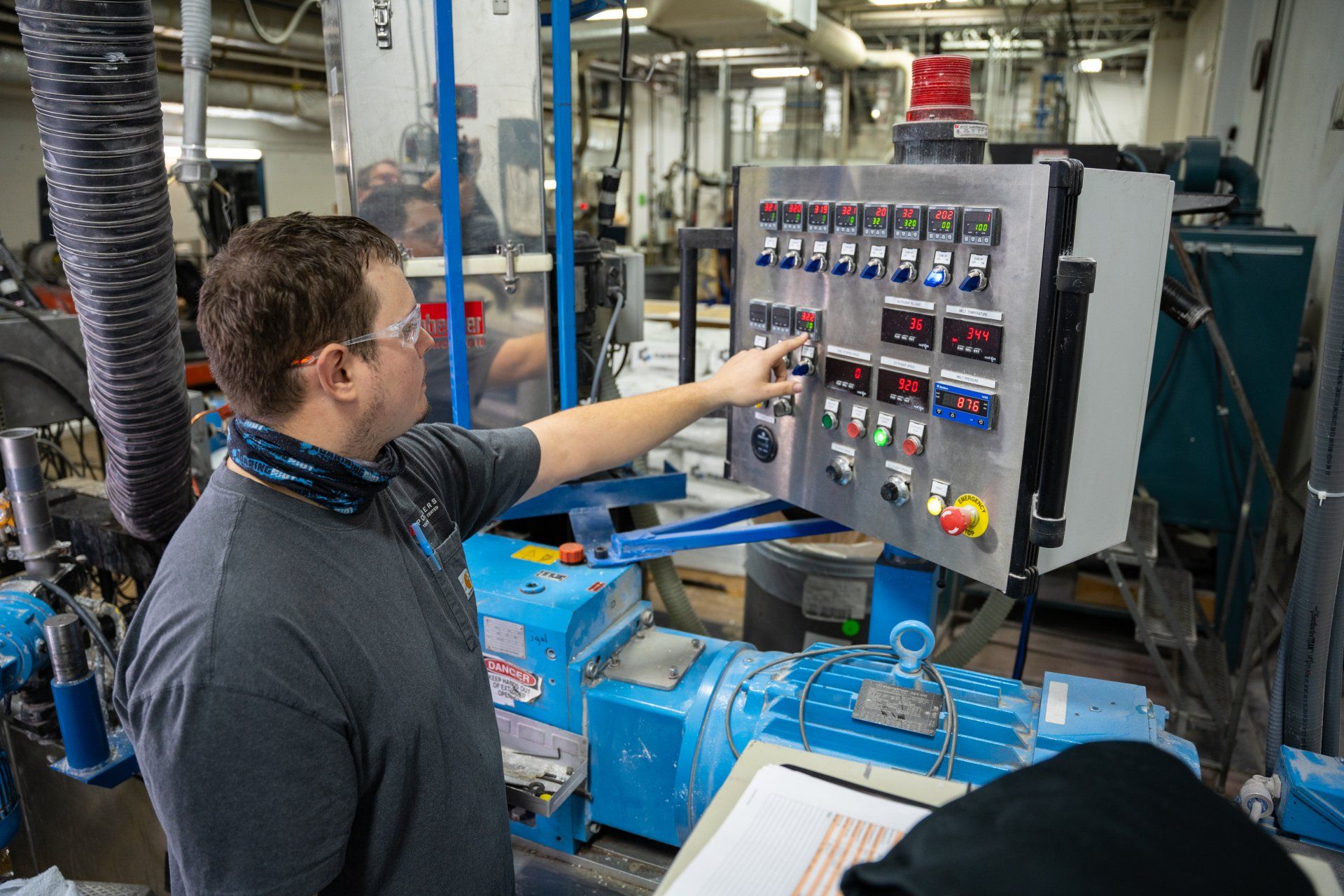

The Masterbatch Manufacturing Process

The Polymers Technology Center houses three compounders to help streamline masterbatch processing. The machines are fed the blend and the host polymer. It is then mixed in the extruder until it becomes the material it is designed to be. Polymers Tech's facility houses the latest equipment, providing an array of mixing properties, product handling capabilities, and quality results.

Any processing challenge requires skill and expertise to overcome. Our production staff is experienced in incorporating the right fillers and additives to refine your product. Our technicians know how and when to add the right fillers and additives into the resin carrier, even fillers that are challenging to disperse.

Common challenges include determining the best method to introduce the masterbatch, dealing with vehicles such as pellets to powders to liquids, assuring accurate dosage, and achieving uniform dispersion. The result is a homogenous product that will be ready for pilot testing and, eventually, commercial use.